Solar systems for use in energy generation, such as photovoltaics (PV) and concentrated solar power (CSP), are a fast-growing market with enormous potential for reducing CO2 emissions. The International Renewable Energy Agency (IRENA) predicts that PV installed capacity will reach 3 terawatts (TW) by 2030 and 8.5 TW by 2050. In other words, we are still at the very beginning of the global growth curve for solar technology deployment.

AGC’s float glass technology is highly scalable and extremely reliable, providing a sustainable solution for the European solar value chain and helping our domestic manufacturing industry meet the growing demand for solar power.

We are a one-stop shop for our customers: we manufacture float glass, apply coatings and process our products, including grinding, drilling and thermal toughening. Everything is highly automated, precise and efficient.

Why choose AGC for solar glass?

We have one of the most stable and durable anti-reflective (AR) coatings on the market today.

Our production process includes the world’s largest continuous vacuum coating systems for producing high-end functional films on glass. The SiOx-based AR coating can be applied to ribbons of glass measuring up to 21 m². This is done quickly and efficiently while delivering consistently high quality. The ribbons aren’t cut into the desired sizes until after they are coated, ensuring maximum flexibility in the desired final sizes.

More info on: https://www.agc-solar.com

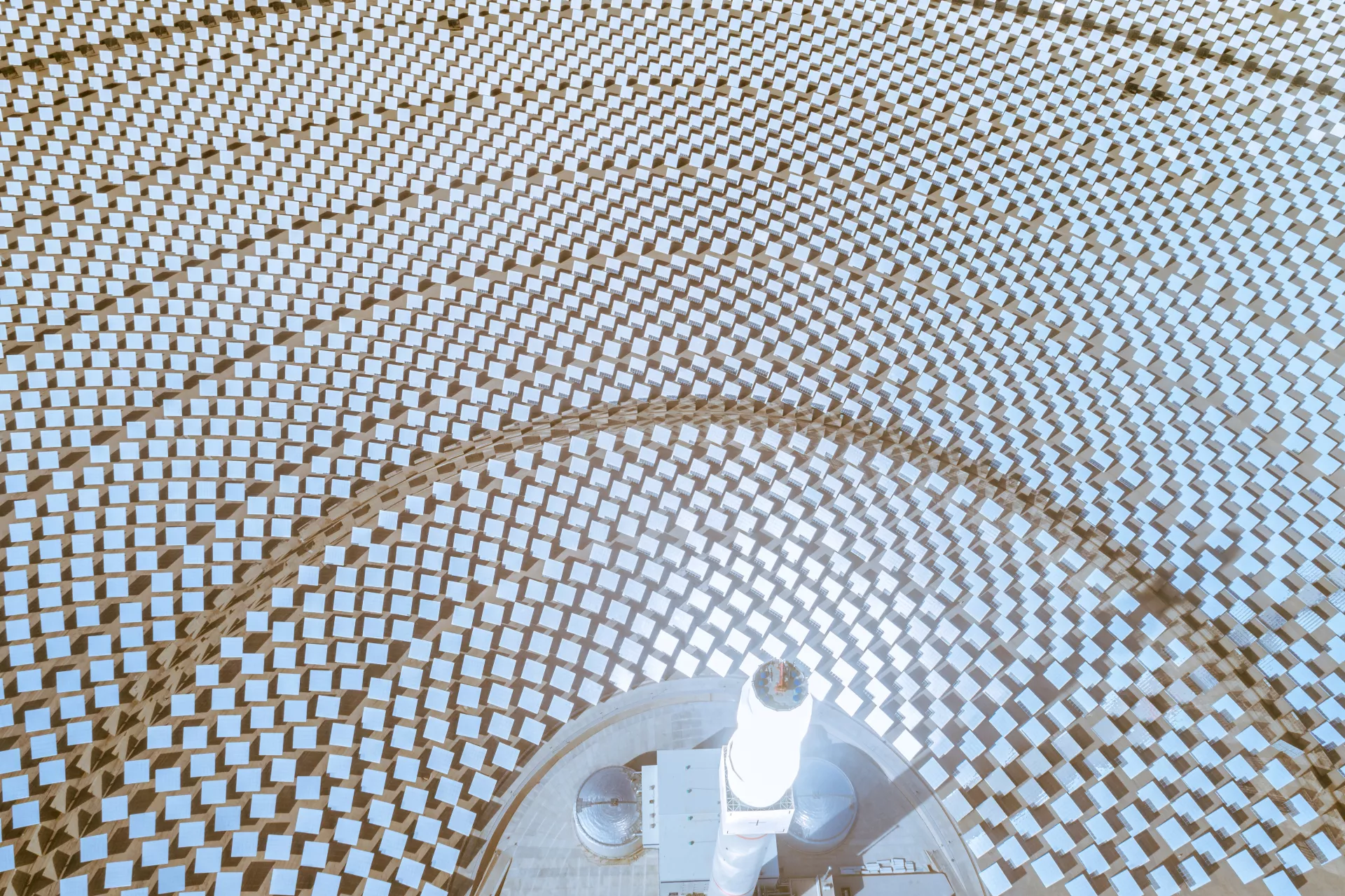

AGC is the leading manufacturer of flat solar mirrors, with years of proven expertise. As a fully integrated company, AGC offers a full range of products dedicated to CSP applications: from sand and low-iron float glass substrates made by our highly specialised float glass plants to high-end solar mirrors.

Maximum energy efficiency

Available in thicknesses from 1 mm to 4 mm, AGC’s Sunmax Premium Reflect mirrors are ideal for all kinds of CSP applications, such as parabolic dishes, parabolic troughs, Fresnel collectors and heliostat power plants. Solar mirrors reflect the maximum amount of irradiating energy. When selecting a solar mirror, it is critically important to find one where the glass itself absorbs the lowest possible amount of valuable energy. And since we have so many years of experience and expertise in manufacturing float glass as well as high-reflectivity solar mirrors, AGC also provides high-transmission solar glass substrates, such as Sunmax Premium.

We guarantee consistently high availability of materials and systems, not only for smaller projects but also for large projects covering several million square meters.

AGC focuses on the industrial production and distribution of ultra-low-iron solar float glass with a highly robust and durable anti-reflective coating, such as Sunmax Premium HT. We specialise in 2 mm to 4 mm front and rear panels for the latest generation of glass-glass photovoltaic modules.

Super thin and super strong

Glass-glass photovoltaic modules have a particularly high output stability and are extremely durable. The advantage this gives them over traditional PV modules is further enhanced by our ultra-durable anti-reflective coating. Our single-side coated 2 mm glass delivers high output with an energy transmission (Te,PV) of 94% and guarantees consistently high system performance.

Solar thermal systems are becoming increasingly efficient, and in fact are already helping to offset CO2 emissions from lignite-fired power plants. AGC Glass Europe’s ultra-durable anti-reflective coating ensures consistently high system performance even under the most stringent environmental conditions and thus provides maximum economic efficiency and investment reliability.

The perfect solution for output-stable large collectors using single or double glazing

Our ultra-low-iron Sunmax Premium HT glass features an anti-reflective coating on both sides and is ideal for large high-performance collectors used in district heating networks, industrial process heating systems, apartment blocks and solar cooling. Whether used on single or double-glazing, our AR coating is not only efficient and durable, it’s also easy to process.

Thermally tempered glass in thicknesses from 2 mm to 5 mm is available in sizes up to 2600 mm x 1500 mm. Our glass processing system is optimised for high-quality mass production of thermally tempered glass.